FabLab Safety & Tools

GENERAL SAFETY RULES & REGULATIONS

1. Students are not allowed to enter and work in any laboratory or workshop in the

absence of the lecturer-in-charge or Technical Supporting Officer (TSO).

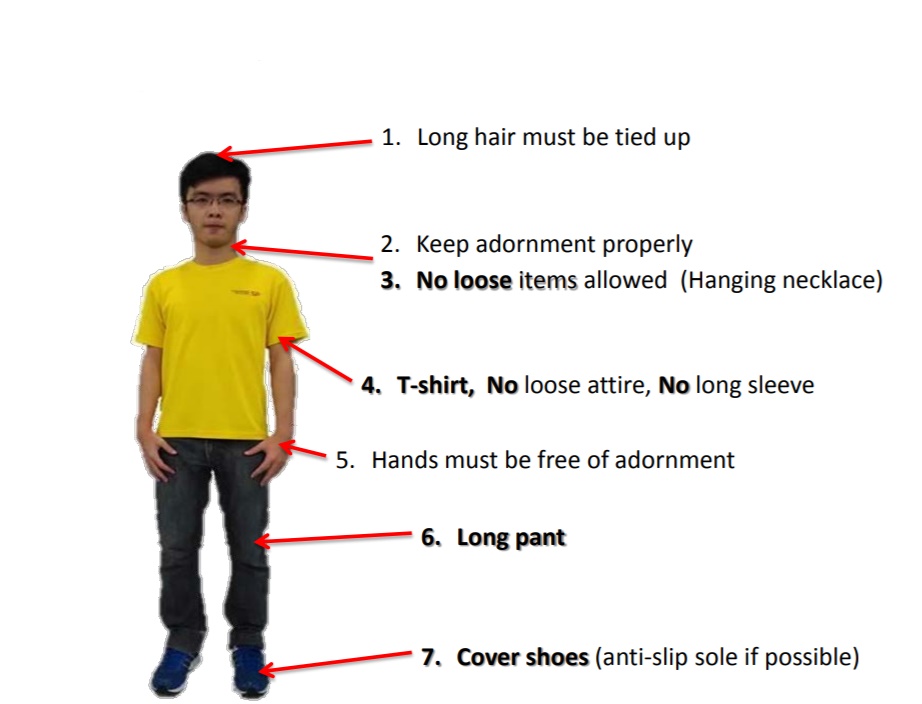

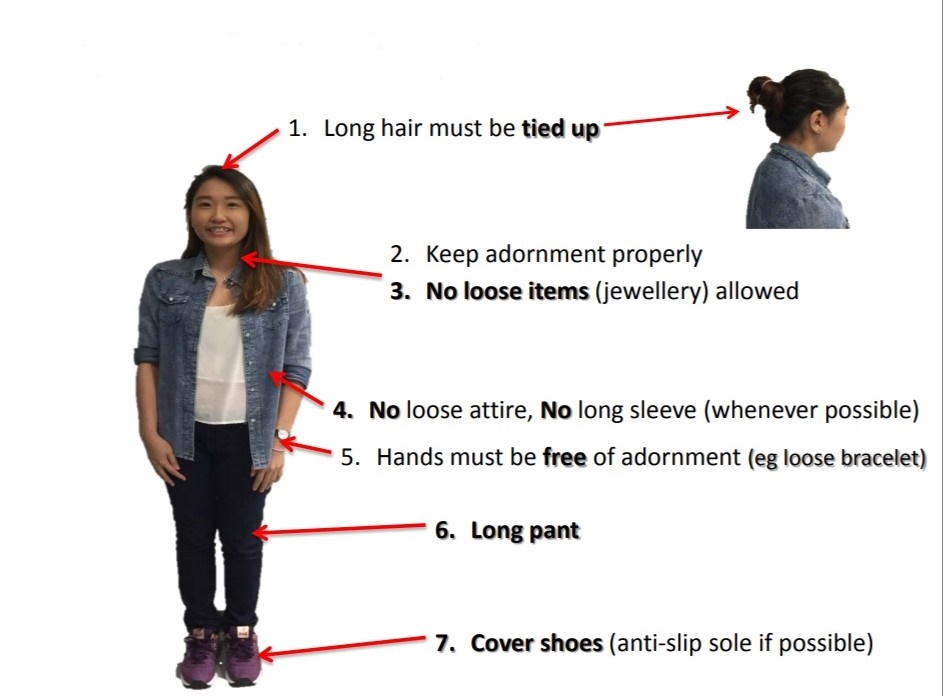

2. Students must be properly attired according to the guidelines below :

a. Collared shirt or T-shirt and full-length trousers.

b. Do not wear loose-sleeved clothing and jewellery.

c. Do not use compressed air to clean your clothing.

d. Covered shoes must be worn at ALL time – NO open tops or open toes.

e. Students with long hair must tie up their hair to avoid entanglement with rotating machinery.

f. Certain laboratories and workshops required the use of additional safety equipment and

Personal Protective Equipment (PPE) such as goggles, safety glasses, masks, gloves, ear

plugs/earmuffs as instructed to protect against any workplace and machine hazards.

3. Eating and drinking are strictly prohibited in laboratories and workshops.

4. Students must switch off their mobile phones while working in laboratories and workshops.

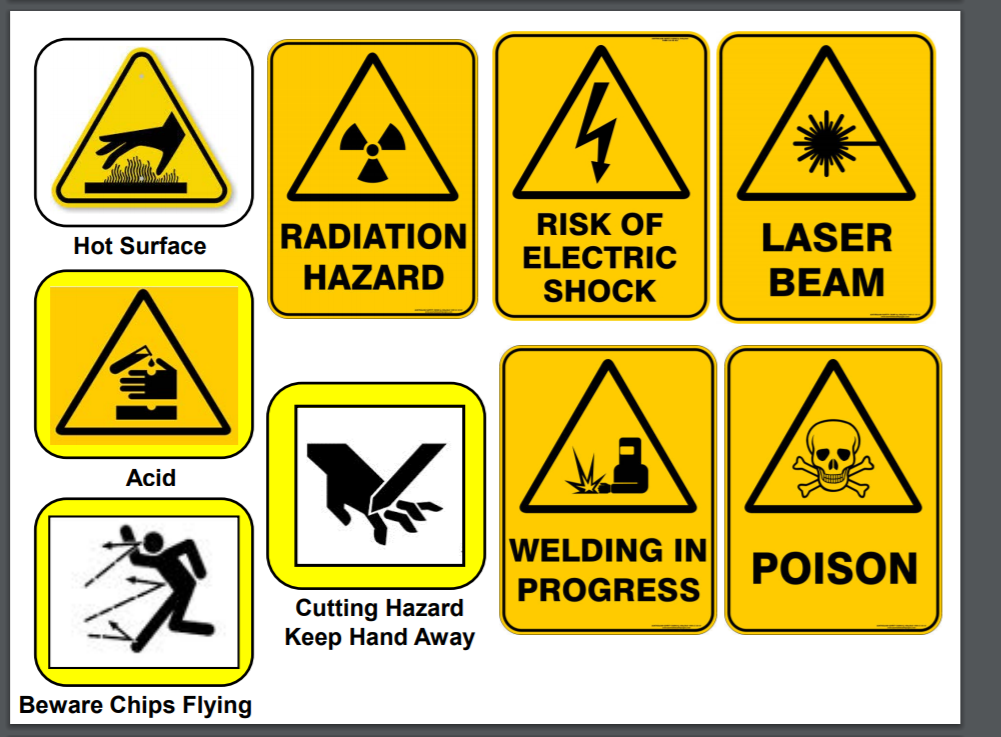

5. Be alert. Observe and abide all warning signs and safety notices.

6. Be familiar with the location of the first-aid box, safety eye-wash and /or shower, chemical spill kit

within each laboratory and workshop.

7. Know the location of all fire escape exits and assembly area.

8. No mischievous or malicious behaviour is allowed in the laboratory/workshop.

9. Safe operating or work procedures must be referred or adhered to.

10. Do not operate machines or equipment until you have been properly instructed by your lecturerin-charge or TSO.

11. Seek help from your lecturer-in-charge or TSO whenever you are in doubt.

12. Do not tamper with all safety devices and machine guards.

Fab Lab and Workshop Safety Rules Page 2

13. Do not take unsafe short cuts or by-pass any safety devices or controls.

14. Keep your work area clean before leaving the laboratory/workshop.

15. Report any UNSAFE conditions or UNSAFE acts to your lecturer-in-charge or TSO.

16. Report at once to your lecturer-in-charge or TSO if you are feeling unwell or injured.

17. For students doing a final year project in a laboratory or workshop, you have to conduct a risk

assessment (RA) of the project and submit the conducted risk assessment form to your project

supervisor for approval and signature. The approved and signed RA form must then be submitted

to the project workshop/ laboratory for filing. You can request the blank risk assessment form

from the Technical Support Officer or download the softcopy from Blackboard.

SPECIFIC SAFETY RULES & REGULATIONS IN FAB LAB AND MACHINE SHOP

It is recommended that you familiarise yourself thoroughly with the operation of the machine and

adhere strictly to the following safety rules and regulations. If in doubt, please ask the Instructor or

Technical Support Officer (TSO). In this way, we can prevent accidents that may result in operator’s

injury, costly damage to the machine, or scrapped work-pieces.

1. A clean, neat, orderly machine and work area is the first step in safety. Keep all guards and covers

in place and all machine cabinet doors closed.

2. Do not operate machines or equipment until you have been properly instructed and authorized to

do so by your Instructor/TSO.

3. Do not start the machine or spindle until the work-piece and work-holding devices are securely

fastened.

4. During any activity that requires the handling of work-holding devices, tools, measuring devices, or

work-piece parts in the cutting zone, the machine’s motors must be in the stationary mode.

5. Know the position of the Emergency Stop push-button of the machine. Activate it during

emergency situation.

6. Do not lean on any moving parts when the machine is in operation.

7. If you must remove hot tooling or sharp tools, switch off the machine and put on the hand gloves.

8. Never clear chips when the spindle is rotating. Never remove chips with your bare hands. Use a

brush or tool designed for that purpose.

9. When operating machine, it requires your undivided attention. No “horseplay” or “monkey about”

is allowed in your work area. If you need to attend to another matter, stop the machine until you

can give it the full attention required.

Emergency Procedures:

When making an emergency call, it is essential to give precise information as follows:

- Name of caller

- Location (block and room number)

- Nature of emergency e.g. fire, explosion, violent or abusive behaviour, etc.

Emergency Contact List:

- 995 - Ambulance/Fire

- 999 - Police

- 67721206/67721234 - General Office

- 67721234 - SP Emergency Hotline

Incident & Accident Reporting

- Report all work related injuries, no matter how minor, promptly to technical support staff or supervising staff.

- Contact the school’s general office, 67721206 or call 67721234 when treatment to injury is required.

- Do not leave injury unattended or without treatment.

Male and Female Dress Code

Safety Symbols

There a 3 primary areas at a machine where hazards can be encountered.

- Machine's perimeter:

Area around a machine, where falling objects, flying debris or other hazards can be encountered. - The drive train:

The moving parts that run the machine. - Points of operation:

Location where a machine's mechanical or electrical energy is used to cut, bend or otherwise process materials.

Mechanical Hazards of Machinery

- Entanglement Hazards:

Entanglement arise when loose clothing, hair or loose item got caught with the moving parts of a machine. - Cuttng Hazards:

Machines with moving cutting elements are dangerous. They can cause severe injury (eg. deep cuts, amputations) due to its own momentum when they come into contact with a worker’s body. - Draw-in Hazards:

Injuries can occur when a body part is drawn-in by inrunning nip points formed by two counter-rotating parts or between rotating and tangentially moving surfaces. Example: Gears. - Impact Hazards:

Impact hazards relate to objects that strike the human body, but do not penetrate it. The severity of an impact hazard depends on the speed, force and inertia of the moving machine part during operation or upon ejection from the machine . - Shearing Hazards:

Parts of machines that move past each other or stationary objects can cause a shear point resulting in a crushing or cutting action. - Crushing Hazards:

It is caused when part of the body is caught between either two moving parts of machinery or a moving part and a stationary object. - Friction & Abrasion Hazards:

Friction burns and abrasions occurs when encountering rough surfaces moving at high speed e.g. sanding machine, grinding wheel etc. can cause abrasion injuries.

Non-Mechanical Hazards of Machinery

- Fall from Heights Hazards

- Noise Hazards

- Electrical Hazards

- Heat-related Hazards

- Chemical Hazards

- Fatigue

- Ergonomic Risk factors

Singapore Polytechnic FabLab Capabilities:

- 3D printing

- CNC-Milling

- Circuit production

- Laser

- Precision milling

- Vinyl cutting

Commonly used household tools:

- Hammer

- Metal Rule

- Spanner

- Electric Drill & drill bit

- Measuring Tape

- Ladder

- Wire cutters

- Ladder

- sorted screws

- Duct Tape

10 Must-have Tools for Any Workshop

Also,students are required to install AutoDesk Fusion 360.